We’re thrilled to share that our High-Temperature Heat Pump was featured in The Hindu BusinessLine! This marks another milestone in our journey toward advancing energy efficiency and sustainability. The industrial sector is undergoing a transformative shift as businesses seek innovative solutions to enhance energy efficiency while reducing carbon emissions. Aspiration Cleantech Ventures proudly presents the High-Temperature Heat Pump, recently featured in The Hindu BusinessLine for its groundbreaking contributions to sustainable industrial heating.

What Makes the High-Temperature Heat Pump Unique?

Our High Temperature Heat pump (120°C)Heat Pump is the first of its kind in India, capable of delivering water outlet temperatures up to 120°C. Designed with a cascaded system, it integrates both Low Temperature (LT) and High Temperature (HT) circuits, ensuring optimal performance and energy efficiency. Additionally, we offer customized solutions tailored to meet clients’ specific peak process load requirements, providing a seamless, efficient, and effective heating solution.

Our Technology Advancement

- Energy Efficiency:

- Improves energy efficiency significantly.

- Reduces operational costs and carbon emissions in industrial applications.

- Renewable Energy Utilization:

- Leverages renewable energy sources for efficient heating solutions.

- Durability:

- Designed for long-term performance, even in demanding industrial environments.

- High System COP (Coefficient of Performance):

- Offers a COP ranging from 2.2 to 3.6.

- Ensures cost-effective and sustainable operations.

Specific Features:

Integration Type:

- Cascaded design, incorporating both Low Temperature and High Temperature circuits for enhanced performance.

Temperature:

- Achieves a maximum temperature of 120°C at the hot side and 7°C at cold side

Coefficient of Performance (COP):

- Offers an overall system COP ranging from 2.2 to 3.6.

Refrigerant:

- Uses refrigerants with:

- Low Global Warming Potential (GWP).

- Non-Ozone Depleting Potential (ODP).

Compressors:

- Equipped with high-performance screw compressors.

Heat Sources:

- Utilizes multiple sources, including:

- Ambient heat.

- Chiller heat.

- Compressor waste heat.

- Any other process fluid heat.

Possible Output:

- Delivers:

- Hot water at a maximum of 120°C.

- Low-pressure steam at 0.8 bar.

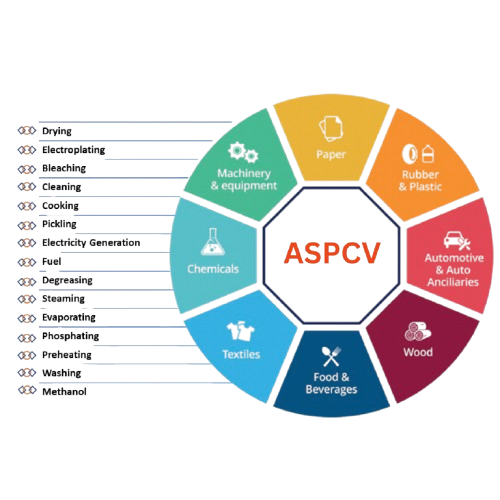

Industries worldwide rely on various processes to enhance efficiency, productivity, and sustainability. From drying and steaming to electroplating and bleaching, these processes play a crucial role in manufacturing, energy production, and chemical treatment. Let’s explore some key industrial applications and the sectors benefiting from them.

INDUSTRIES WE WORK FOR

The listed processes are fundamental across industries such as textiles, food & beverages, chemicals, automotive, rubber & plastics, wood, paper, and machinery. By optimizing these operations, industries can improve efficiency, reduce waste, and enhance product quality.

Industries Are Replacing Fossil Fuels with Heat Pumps: Real-Life Case Studies

As industries strive for decarbonization and energy efficiency, many are making a crucial shift from fossil fuels like LPG, diesel, and coal to sustainable solutions such as industrial heat pumps. This transition not only reduces carbon emissions but also brings significant cost savings and operational efficiency.

Why Are Industries Switching?

- High Operational Costs of Fossil Fuels – Rising fuel prices make heat pumps a more cost-effective alternative.

- Stringent Environmental Regulations – Governments worldwide are pushing for reduced carbon footprints.

- Energy Efficiency Gains – Heat pumps can recover and reuse waste heat, making processes more efficient.

- Sustainability Commitments – Companies aiming for net-zero goals are adopting cleaner technologies.

REAL TIME CASE OF AN AUTOMOTIVE INDUSTRY

| DESCRIPTION | BEFORE | AFTER |

| HEATING SOLUTION | Hot water generator | High Temperature heat pump |

| ENERGY SOURCE | Diesel | Electricity |

| INSTALLED CAPACITY | 465 kW | 162 kW |

| COST OF HEATING SOURCE | Rs. 90 per Liter | Rs. 8 / kWh |

| CONSUMPTION PER DAY | 330 Liters | 1980 kW |

| OPERATIONAL COST | Rs. 1.03 Crores | Rs. 41.71 Lakhs |

Combined Annual Savings on Heating and Cooling – Rs. 69.86 Lakhs

Smarter Heating for Better Efficiency

High-temperature heat pumps are transforming industrial heating by cutting costs, improving energy efficiency, and streamlining operations. As seen in real-world applications, businesses can reduce energy use, lower expenses, and enhance performance by upgrading to smarter heating solutions.

At Aspiration Cleantech Ventures, we’re dedicated to helping industries achieve better efficiency with customized high-temperature heat pump systems. With energy costs rising, making the switch to a more efficient heating process is a smart business decision.

Search